Cleaning air…one cfm at a time.

Applications

common industrial applications

Innovative solutions for even the most challenging applications. You’ll find our exceptional air cleaning equipment being utilized by many different types of facilities in a range of applications. Below are some examples.

Abrasive blasting is a process where castings or other metal parts are surface cleaned with a high velocity stream of particles such as sand, steel, shot, plastic beads, or grit. Good filtration design is important for worker visibility and health protection, improved part quality, reduced housekeeping, and OSHA/EPA compliance.

CNC machining could produce coolant mist or dry dust depending on the process and material being worked. If the machine tool is enclosed, a small collector could be machine mounted or several machines could be ducted to a larger collector. If there is not a good enclosure, a source capture or ambient air solution could be used to control the airborne contaminants.

Food processing covers a large range of applications including grain handling, grain processing, mixing ingredients, packaging, cooking and frying. We have the complete range of air cleaning equipment to handle any application. Typically, any organic dust particulate is combustible and requires explosion protection.

These material finishing processes produce a wide range of particulate that is most commonly controlled with source capture ducted to a dust collector or performed in an environmental control booth. Buffing and polishing could also create particulate that is combustible or explosive when collected.

Quartz is the most common form of crystalline silica, OSHA has a National Emphasis Program (NEP) for Crystalline Silica exposure and has established a strict Permissible Exposure Limit, or PEL, to which workers may be exposed. Most severe exposure occurs from abrasive blasting, foundry operations including casting cleaning and refractory brick lining maintenance, cement and brick manufacturing, and tool and die.

Drying of washed parts before painting or drying bottles/cans before labeling are common applications performed by Sonic blow off systems. Typical Sonic systems are 14X more energy efficient vs. systems that use compressed air.

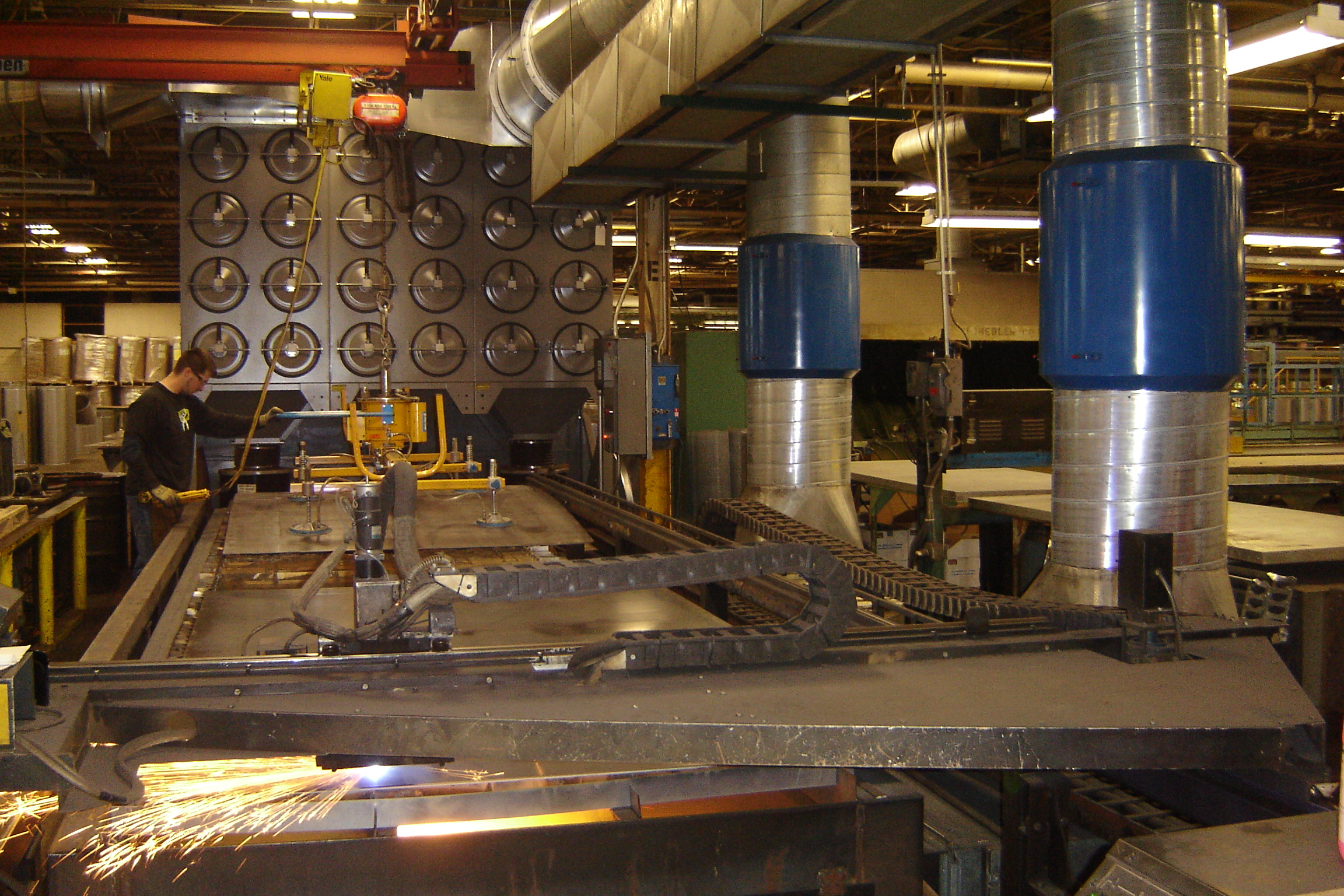

These metal cutting processes generate a heavy amount of fume/smoke. If the process is done on a CNC cutting table, the best approach is to pull air down through the material sheet being cut and utilize a dust collector ducted to the base of the table.

Welding is a metal joining process that creates thermally generated fume/smoke. Weld fume consists primarily of sub-micron particulate that can lead to health issues over time. Air cleaning solutions can include source capture, containment, or ambient air filtration using “push-pull” arrangements.

Woodworking generates dust from processing wood material. Saw dust could be created from sawing, planning, routing, and sanding. Common applications include school wood shops, industrial shipping departments, and furniture/cabinet shops. Dust is generally considered combustible and explosive.

Industrial fans and blowers for air and material handling, ventilation, cooling, heating, paint booths, etc.

Free on-site consultations for all projects.

Air Equipment Sales Inc

P.O. Box 802

1035 Lincoln Rd, Suite 101B

Bettendorf, IA 52722

Phone: 563-359-0333

Toll-Free: 1-800-747-0333

Fax: 563-359-0334

sales@airequipsales.com

Contact Persons:

Brian Melvin

Dave Deasy